What's the difference between Epoxy and BPANI Inner Coatings?

Bare metal surfaces, like raw aluminium, are vulnerable to corrosion.

To keep your product in top-notch condition, it's important to ensure that there's no contact between the beverage and any unprotected metal surfaces. That's why cans have an ultra-thin protective inner coating which helps to keep your beverage safe and extends its shelf-life.

At NOMOQ, we offer two of the most commonly used inner coatings: BPANI and Epoxy. In this article, we'll be explaining the differences between those two can types.

Epoxy vs BPANI

Chemical Composition

The main difference between these two inner coatings is their chemical composition and the presence of Bisphenol A (BPA) in Epoxy varnishes.

Bisphenol A (BPA) is a "plasticiser”, a chemical agent widely used in industry in the production of plastics, paints, and coatings. BPA is considered to be a substance that acts similarly to hormones and may contribute to the development of various diseases. Due to these risks, its use is regulated or banned in some countries, such as France.

Epoxy Coatings

Epoxy coatings are made from a combination of epoxy resins and curing agents, such as amines or phenolic resins. Epoxy coatings often contain BPA, which is a key component of many epoxy resins. It makes cans resistant to corrosion and prevents any metal traces that could lead contamination from contact with the contents.

BPANI Coatings

BPANI coatings are designed to avoid the use of BPA. BPA-NI or BPANI (Bisphenol A Non-Intent) means that BPA was not intentionally added during the manufacturing processes. BPANI coatings typically use polyester-based resins or other alternative materials to achieve performance characteristics similar to Epoxy coatings without the presence of BPA; however, it may be that a substance contains traces of BPA because the smallest amounts have accidentally gotten into the product, e.g. through contact with other substances. So BPANI is not always BPA free.

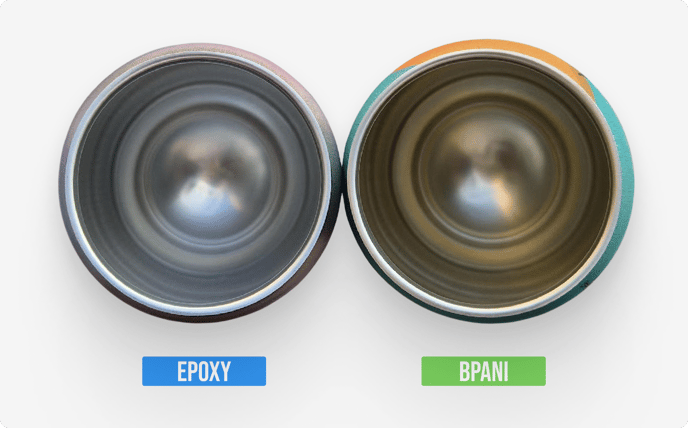

Visual difference between Epoxy and BPANI inner coating

Visual difference between Epoxy and BPANI inner coating

Properties and Applications

Both types of coatings have their own properties and applications. The best choice depends on the specific requirements and safety concerns of the final product.

Epoxy Coatings

Epoxy coatings are known for their excellent adhesion, durability, and chemical resistance. They are also good at respecting smells and tastes. They have a wide range of applications, including protective coatings for metal surfaces, coatings for food and beverage cans, and even industrial flooring. However, their BPA content may be a concern in certain cases.

BPANI Coatings

BPANI coatings offer a safer alternative to Epoxy coatings in terms of health and the environment. They are ideal for use in food and beverage containers, as they minimise the risk of BPA leaching into products. In addition, they offer good chemical and mechanical resistance, as well as excellent adhesion and flexibility.

Advantages and Disadvantages

When it comes to choosing the right can type, it's important to consider both the advantages and disadvantages of each option.

| Epoxy | BPANI | |

| Advantages |

✅ Offer excellent adhesion, durability, and chemical resistance, making them suitable for a wide range of applications. ✅ Better at respecting smells and tastes |

✅ Offer good performance in terms of chemical and mechanical resistance, as well as adhesion and flexibility. ✅ With no BPA intentionally added, they're a safer option for health and the environment |

| Disadvantages | ❌ Includes BPA content, which can raise health and environmental concerns in certain cases | ❌ May be slightly less resistant to certain chemicals and have lower durability in some beverages. |

Conclusion

In summary, BPANI and Epoxy coatings each have their own unique advantages and applications. The best choice for your product will depend on its specific requirements and safety concerns.

We want to make sure you make the best choice for your needs, so we've created a feature on our platform to help you out. You can conduct a corrosivity check to see which inner coating would be the best fit for your beverage. We think it's pretty helpful, so why not give it a try?

Learn more about Beverage and Can type Compatibility

If you would like to learn more about beverage and can compatibility, we have prepared a guide for you. This guide explains the importance of checking compatibility and provides information on how to spot damage to your cans, as well as how to avoid it: What is Beverage and Can Type Compatibility?